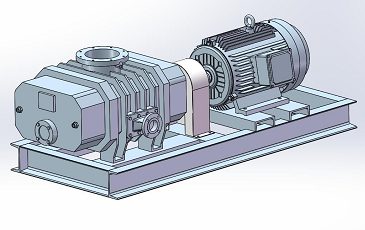

A stainless steel vacuum pump relates to a variable capacity vacuum pump, which has two blade shaped rotors rotating synchronously in opposite directions, and there is a small gap between the rotors and between the rotor and the inner wall of the pump housing without contacting each other. The equipment will have the problem of seal wear when in use. What are the causes of seal wear in the equipment and how to solve them?

Vacuum pump

Today, I have summarized the following points for you, hoping to help you.

1. The shaft is bent and the bearing clearance is too large.

Solution: straighten the shaft, adjust the clearance or replace the bearing.

2. Hard sundries enter the sealing ring of the stainless steel vacuum pump.

Solution: remove the impurities in the sealing ring.

3. The coaxiality error between the sealing ring and the shaft sleeve exceeds the standard.

Solution: replace the worn parts and adjust the coaxiality.

4. The sliding bearing is scratched and deviated.

Solution: adjust or replace the sliding bearing.

5. The chassis of the stainless steel vacuum pump is deformed.

Solution: repair, eliminate deformation effects.

6. Excessive rotor vibration.

Workaround: improve the operation and check the rotor balance if necessary.

Here we are reminded that in order to solve the sealing problem of stainless steel vacuum pump, we should start with prevention and do a good job in the maintenance of seals, which can greatly reduce the wear of seals.