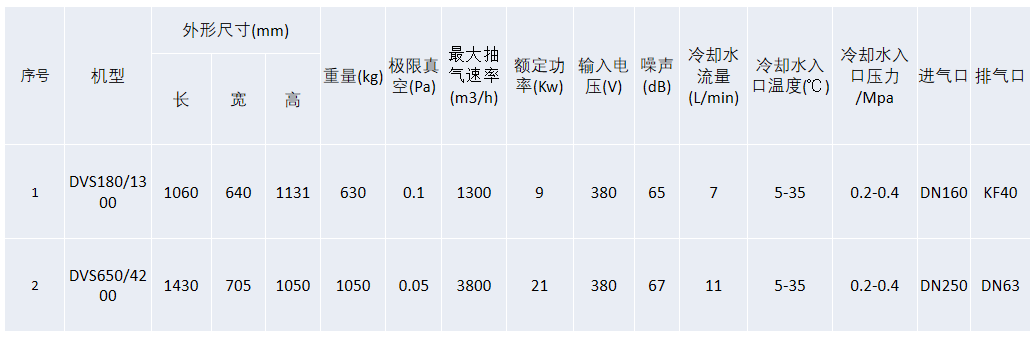

Dvs650/4200 dry vacuum pump uses 180m³/h screw pump as the front stage pump

3800 m3/h roots pump is used as the main pump, and its main performance indexes are as follows:

Limit vacuum: 0.05pa

Air extraction rate: 3800 m³/h (100Hz)

Noise: 67db

Weight: 1050kg

Overall dimension: 1430 mm * 705 mm * 1050mm

Power: 21kw

Water cooled motor: the drive motor is a direct connected water-cooled motor, which is 1/3 smaller than the conventional motor, and the energy density is increased by 30%.

Quick plug interface: the whole set of vacuum unit is integrated in the chassis. The chassis has quick plug interfaces for water, electricity and gas, which is convenient for quick installation on site.

Advanced screw profile design: the front pump of the unit is a water-cooled oil-free dry screw vacuum pump. The advanced screw profile design ensures the low temperature, low noise and efficient operation of the dry pump.

Compatibility: suitable for extracting condensing gas and a certain amount of solid particle impurities.

Gas purging: the gas purging interface at the air inlet can be selected and used according to the actual process conditions. Dry nitrogen / compressed air purging helps to completely discharge the condensable gas. It can also be used to help warm up the vacuum pump at low temperatures.

Cleaning of pump chamber: the pump chamber can be flushed with nitrogen, steam, solvent, etc.

Composite seal structure: labyrinth seal combined with nitrogen seal can effectively prevent process gas from leaking from the pump cavity seal to the oil tank, which will degrade the performance of lubricating oil and cause damage to the pump.

Filter in front of the pump: the air inlet of the vacuum pump can be equipped with a suitable filter device according to the actual working conditions to avoid damage to the pump caused by foreign matters to the greatest extent.

Pump exhaust port configuration: the system exhaust port is equipped with water-cooled silencer and check valve to reduce the exhaust temperature and prevent gas backflow.

Note: The technical parameters of our products are for reference only, and all are subject to the actual delivery.